Copy of `Inside Metals - Mining glossary`

The wordlist doesn't exist anymore, or, the website doesn't exist anymore. On this page you can find a copy of the original information. The information may have been taken offline because it is outdated.

|

|

|

Inside Metals - Mining glossary

Category: Agriculture and Industry > Metal terms

Date & country: 10/11/2016, UK

Words: 102

|

WasteBarren rock or mineralized material that is too low in grade to be economically processed.

Working CapitalThe liquid resources a company has to meet day-to-day expenses of operation; defined as the excess of current assets over current liabilities.

Zinc DustFine zinc metal used to precipitate gold and silver from solution. The precious metal values precipitate into a fine sludge and the zinc metal replaces these values in solution.

Total Cash CostCash Operating Cost plus production royalties and mining taxes.

TonA `short` ton measure of weight containing 2,000 pounds and equal to 0.907 Tonnes.

TonneA `metric` tonne weight measure containing 1,000 kilograms.

Total Production CostTotal Cash Cost plus depreciation and amortization.

Troy OunceA measure of weight in which precious metals are sold. One Troy Ounce contains 31.1 grams. A kilogram contains 1,000 grams.

VeinA fissure, fault or crack in a rock filled by minerals that have travelled upwards from a deeper source.

TailingsCrushed or finely ground waste rock from which valuable minerals or metals have been extracted.

Stripped CarbonActivated coconut shell carbon which has had the precious metal values removed by chemical processing in preparation for reactivation and recycling back to the stripping circuit.

Strip RatioThe ratio of tons of overburden waste material to tons of ore in an open pit mine. The waste rock removed in order to expose the orebody in an open pit mine is hauled only once to a waste disposal area, in contrast to strip mining where waste rock is replaced to reclaim the flat lying mined-out area.

Strip VesselThe closed container in which loaded carbon is placed to remove (desorb) precious metals from the surface of the activated carbon.

SolutionsVarious water solutions in the leaching circuit, from fresh make-up water, to pregnant solution containing significant amounts of precious metals and leaching reagents (chemicals), to barren solution which contains small quantities of valuable metals but mainly the leaching reagents.

Sodium CyanideA chemical used in the milling and heap leaching of gold ores to dissolve gold and silver.

Smelting FurnaceA furnace, usually cylindrical, used to melt concentrated valuable metals and minerals and further upgrade them by slagging off gangue minerals with the use of chemical flux materials.

Rod MillA rotating steel cylinder that uses steel rods as a means of grinding ore.

Run-of-Mine(ROM) Mined ore of a size that can be processed without further crushing.

SlagThe vitreous mass of glass material separated from the fused metals in the smelting process.

RefractoryGold mineralization normally requiring more sophisticated processing technology for extraction, such as roasting or autoclaving under pressure.

Reverberatory FurnaceA long, flat furnace used to slag gangue minerals and produce a matte of sulfide minerals.

RecoverableThat portion of metal contained in ore that can be extracted by processing.

RefiningTo process material to a pure state. Precious metal bullion is fire refined to high purity gold and silver.

Put OptionA financial instrument that provides the right, but not the obligation, to sell a specified number of ounces of gold at a specified fixed price on or before a given date.

ReclamationThe process of returning land to another use after mining is completed.

Proven Mineral Reservethe economically mineable part of a Measured Mineral Resource demonstrated by at least a preliminary feasibility study. This study must include adequate information on mining, processing, metallurgical, economic, and other relevant factors that demonstrate, at the time of reporting, that economic extraction is justified.

PlacerA deposit of sand and gravel containing valuable metals such as gold, tin, or diamonds.

Platinum Group Metals(PGMs) The two triads of the elements ruthenium, rhodium, palladium and osmium, iridium, platinum, are grouped together under the name platinum metals. The platinum metals are all found native, almost always associated with each other and mixed with gold, silver, copper, nickel, and iron.

Probable Mineral Reservethe economically mineable part of an Indicated, and in some circumstances a Measured Mineral Resource demonstrated by at lease a preliminary feasibility study. This study must include adequate information on mining, processing, metallurgical, economic, and other relevant factors that demonstrate, at the time of reporting, that economic extraction can be justified.

Net Smelter Return Royalty(NSR) A defined percentage of the gross revenue from a resource extraction operation, less a proportionate share of transportation, insurance, and processing costs.

Non-RefractoryOre containing gold or other metal that can be satisfactorily recovered by basic gravity concentration or simple cyanidation methods.

OreA mixture of valuable minerals and gangue minerals from which at least one of the minerals can be extracted at a profit. An orebody is a natural concentration of valuable material that can be extracted and sold at a profit.

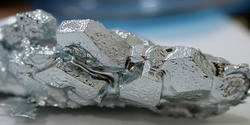

Native MetalA metal occurring in nature in pure form, uncombined with other elements.

MuckOre or rock that has been broken by blasting.

Mineral Resourcea concentration or occurrence of natural, solid, inorganic or fossilized organic material in or on the Earths crust in such form and quantity and of such a grade or quality that it has reasonable prospects for economic extraction. The location, quantity, grade, geological characteristics and continuity of a Mineral Resource are known, estimated or interpreted from specific geological evidence and knowledge.

MineralA naturally occurring homogeneous substance having definite physical properties and chemical composition and usually a crystal form.

Mineral Reservethe economically mineable part of a Measured or Indicated Mineral Resource demonstrated by at least a preliminary feasibility study. This study must include adequate information on mining, processing, metallurgical, economic and other relevant factors that demonstrate, at the time of reporting, that economic extraction can be justified. A Mineral Reserve includes diluting materials and allowances for losses that may occur when the material is mined.

MetallurgyThe study of extracting metals from their ores.

MillA processing plant which treats ore for the purpose of upgrading the mineral content into a higher grade product called a concentrate, which is further treated, and disposing of the waste minerals to an impoundment area.

MineAn excavation from which ore or minerals are extracted. The ore may be removed from an open pit on surface by truck haulage or from underground openings (workings) via a shaft and hoist equipment to the surface for further transport.

Merrill-Crowe (M-C) CircuitA process which recovers precious metals from solution by first clarifying the solution, then removing the air contained in the clarified solution, and then precipitating the gold and silver from the solution by injecting zinc dust into the solution. The valuable sludge is collected in a filter press for drying and further treatment.

Measured Mineral Resourcethat part of a Mineral Resource for which quantity, grade or quality, densities, shape, physical characteristics are so well established that they can be estimated with confidence sufficient to allow the appropriate application of technical and economic parameters, to support production planning and evaluation of the economic viability of the deposit. The estimate is based on detailed and reliable exploration, sampling and testing information gathered through appropriate techniques from locations such as outcrops, trenches, pits, workings and drill holes that are spaced closely enough to confirm both geological and grade continuity.

LeachingA chemical process for the extraction of valuable minerals from ore.

Jaw CrusherA machine in which rock is broken by the action of swinging steel plates.

JigA piece of milling equipment used to concentrate high density minerals by gravity on a screen submerged in water, either by the reciprocating motion of the screen or by the pulsation of water through it.

Inferred Mineral Resourcethat part of a Mineral Resource for which quantity and grade or quality can be estimated on the basis of geological evidence and limited sampling and reasonably assumed, but not verified, geological and grade continuity. The estimate is based on limited information and sampling gathered through appropriate techniques from locations such as outcrops, trenches, pits, workings and drill holes.

Indicated Mineral Resourcethat part of a Mineral Resource for which quantity, grade or quality, densities, shape and physical characteristics, can be estimated with a level of confidence sufficient to allow the appropriate application of technical and economic parameters, to support mine planning and evaluation of the economic viability of the deposit. The estimate is based on detailed and reliable exploration and testing information gathered through appropriate techniques from locations such as outcrops, trenches, pits, workings and drill holes that are spaced closely enough for geological and grade continuity to be reasonably assumed.

HedgingTaking a buy or sell position in a futures market opposite to a position held in the cash market to minimize the risk of financial loss from an adverse price change.

Heap LeachA mineral processing method involving the crushing and stacking of ore on an impermeable liner upon which leach solutions are sprayed to dissolve metals such as gold and copper. The metal, in the collected solution flowing from the leach pad is subsequently treated to recover the metals.

Gyratory CrusherA machine that crushes ore between an eccentrically mounted crushing cone and a fixed crushing throat. Typically, it has a higher capacity than a jaw crusher.

GradeThe metal content of ore in Troy ounces per ton or percent. Head grade is the average grade of ore fed into a mill or heap leach metal recovery operation.

GrizzlyA grating, usually constructed of steel rails, placed over the top of a chute or ore pass for the purpose of stopping large pieces of rock or ore that may hang up in the pass.

Gold PrecipitateFine sludge of gold, silver, and zinc. The precious metals are precipitated out of solution by the addition of fine zinc dust.

Gold LoanA form of debt financing whereby a potential gold producer borrows gold from a lending institution, sells the gold on the open market, uses the cash for mine development, then pays back the gold from actual mine production.

FluxA mix of chemical substances that react with gangue minerals to form slags, which are liquid at smelting furnace temperature and low enough in density to float on the molten bath of metal.

Free MillingOres of gold or silver from which the precious metals can be recovered by concentrating methods without resorting to pressure leaching or other chemical treatment.

GangueThe worthless minerals in an ore deposit.

FlotationA milling process in which valuable mineral particles are induced to become attached to bubbles and float away from the waste particles in a solid/solution pulp.

Flow-through SharesShares in an exploration company that allow the tax deduction or credits for mineral exploration to be passed to the investor.

Feasibility StudyAn engineering study designed to define the technical, economic, and legal viability of a mining project with a high degree of reliability.

Filter PressA pressure filter containing cloth leaves which are supported within a closed container to remove solids from a fine solids feed slurry. The solids sludge collected is periodically removed from the filter by opening the filter plates, scraping off the solids and replacing the plates with new and clean filter cloth or filter paper for continued filtering.

Electrolytic RefiningThe process of purifying metal plates that are suspended as anodes in an electrolytic bath. The valuable metal is plated onto refined sheets called cathodes of the same metal which act as starters.

ElectrowinningThe removal of precious metals from solution by the passage of current through an electrowinning cell. A direct current supply is connected to the anode and cathode. As current passes through the cell, metal is deposited on the cathode. When sufficient metal has been deposited on the cathode, it is removed from the cell and the sludge rinsed off the plate and dried for further treatment.

Due DiligenceThe degree of care and caution required before making a decision. A financial and technical investigation to determine whether an investment is sound.

ElectrolysisAn electric current is passed through a solution containing dissolved metals causing the metals to be deposited onto the negatively charged cathode.

DewateringThe process of separating solids from solution by sedimentation in tanks called thickeners or by filtering the solution through filter cloth in filters.

DilutionMixing of ore grade material with non-ore grade waste material in the mining process.

DoreUnrefined gold bullion containing various impurities such as silver, copper and mercury, which will be further refined to near pure gold.

Deaeration TowerA closed tank from which air (oxygen) is evacuated by a vacuum pump on the closed system. As solution flows through a contained media of large surface area, oxygen is removed (boils) from the solution.

DerivativeA collective term for securities whose prices are based on the prices of another underlying investment. Derivatives are essentially a bet on which way the price of the underlying instrument is going and can be used to reduce the risk of (hedge) and investment in the underlying instrument.

Cut-Off GradeA grade level below which the material is not `ore` and considered to be uneconomical to mine and process. The minimum grade of ore used to establish reserves.

CyanidationA method of extracting exposed gold or silver grains from crushed or ground ore by dissolving it in a weak cyanide solution. This may be carried out in agitated tanks in a mill or on ore heaps outside.

Cone CrusherA machine which crushes ore between a gyrating cone or crushing head and an inverted, truncated cone known as a bowl.

ConveyorA rubber reinforced continuous belt supported on rollers called idlers which transports solid materials between stockpiles, surge bins, and feeders. The belt is driven by an electric drive motor at the head pulley.

Cut-and-FillA method of stoping in which ore is removed in slices, or lifts, and then the excavation is filled with rock or other waste material (backfill), before the subsequent slice is extracted.

Complex OreAn ore containing a number of minerals of economic value. The term implies that there are metallurgical difficulties in liberating and separating the valuable minerals.

ConcentrateA fine product separated in the milling process that contains a high percentage of valuable metal.

ConcentratorA milling plant that produces a concentrate of the valuable minerals or metals. Further treatment is required to recover the pure metal.

Common stockShares in a company which have full voting rights which the holders use to control the company in common with each other. There is no fixed or assured dividend as with preferred shares, which have first claim on the distribution of a companys earnings or assets.

ClassifierA mineral processing machine which separates mineral particles according to size and density.

Clarifier FilterA pressure filter containing cloth leaves which support a porous filter medium and filter out all fine solids from relatively clear feed solution. The sludge collected is periodically flushed from the filter on a regular cycle.

CathodeA rectangular metal plate with a negative charge used in electrolytic refining. The deposited metal recovered onto this plate is called cathode metal and is melted into commercial shapes such as bars or ingots.

Cash FlowThe net of the inflow and outflow of cash during an accounting period. Does not account for depreciation or bookkeeping write-offs which do not involve an actual cash outlay.

Cash Operating CostCost per ounce that is equivalent to direct operating expense, including mining and processing, waste stripping and minesite G&A, less production royalties, mining taxes and by-product credits for payable metals recovered.

Carbon-in-Pulp CIP)A method of recovering gold and silver from fine ground ore by adsorption of the precious metals onto fine carbon in an agitated tank of ore solids/solution slurry. This recovery step in the process follows the leaching process which is done in similarly agitated tanks, but without contained carbon.

Carbon-in-Leach(CIL) A method of recovering gold and silver from fine ground ore by simultaneous dissolution and adsorption of the precious metals onto fine carbon in an agitated tank of ore solids/solution slurry. The carbon flows counter currently to the head of the leaching circuit.

CapitalizationA financial term used to describe the value financial markets put on a company; determined by multiplying the number of outstanding shares of a company by the current stock price.

CarbonFine sized granules of activated carbon, typically ground coconut shell because of its hardness.

Carbon-in-Column(CIC) A method of recovering gold and silver from pregnant solution from the heap leaching process by adsorption of the precious metals onto fine carbon suspended by up-flow of solution through a tank.

Capital StockThe total ownership of a limited liability company divided among a specified number of shares.

BondAn agreement to pay a certain amount of interest over a given period of time. A bond may be required to ensure reclamation of a mine site.

BullionMetal formed into bars or ingots.

CalcineConcentrate ready for smelting; the sulfur has been driven off by oxidation.

Call OptionAn option which gives the holder the right but not the obligation to purchase a stated quantity of gold ounces or other metal at a specified price on or before a given date.

BeneficiationThe concentrating or enriching of the valuable minerals in an ore.

Bio-LeachingA processing method that uses bacteria to oxidize refractory sulfide ore to make it amenable to normal oxide ore processing techniques.

Block CavingAn inexpensive method of underground mining in which large blocks or ore are undercut, causing the ore to break or cave under its own weight.

Ball MillA steel cylinder containing about 40% volume of steel balls used to grind ore. The mill is rotated causing the balls to cascade and grind the ore.

AnodeA rectangular metal plate with positive charge cast in a shape suitable for refining by the electrolytic process.

AssayA chemical test by wet or fire methods performed on a rock sample to determine the amount of valuable metal contained.